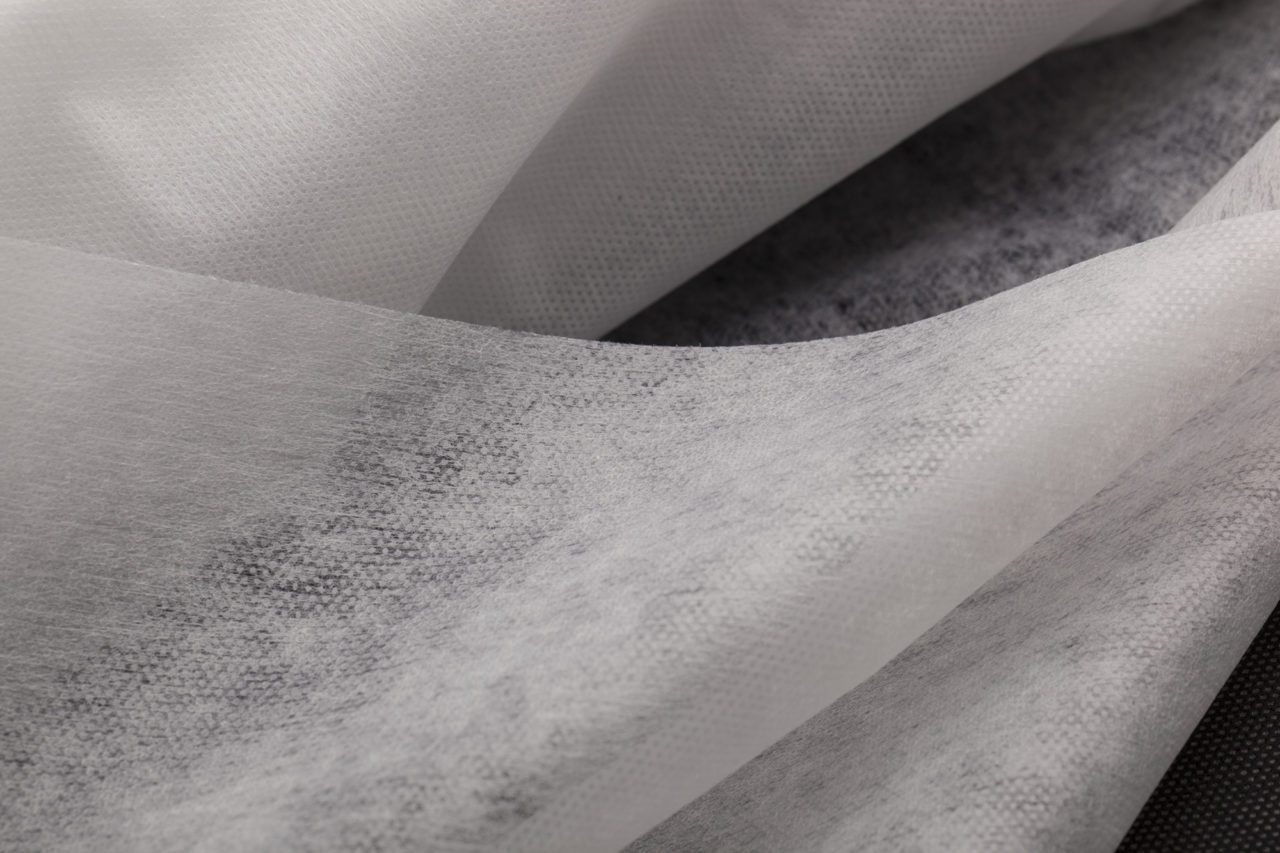

Lentex offers a wide range of high quality products with numerous applications in the automotive industry. In many cases, nonwoven fabrics are often applied in the hidden areas. They seem to have a key value for the automotive industry.

Automotive nonwovens have features important for the final consumer, as well as they improve the production process. They are often combined with other materials, mainly fabrics to create composites that meet the high requirements of the automotive industry. They are used as the outer fabric carriers in the elements of the car’s interior, filtering layers, soundproofing and insulating materials.

The main raw materials used in the production of automotive nonwovens are polyester and polypropylene and mixtures of them. Nonwovens may also be subject to processing operations, eg.: application of thermoplastic powders or thermal stabilisation. They are characterised by high strength, good mechanical performance and high aesthetics. Usability of these products, for many applications, makes them irreplaceable.